high quality vertical suspended sump pump manufacturers

Latest articles

A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

high quality vertical suspended sump pump manufacturers...

high quality vertical suspended sump pump manufacturers 【high quality vertical suspended sump pump manufacturers】

Read MoreThe impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

high quality vertical suspended sump pump manufacturers...

high quality vertical suspended sump pump manufacturers 【high quality vertical suspended sump pump manufacturers】

Read MoreTo reduce wear, reduce the pump discharge pressure to the lowest possible point.

high quality vertical suspended sump pump manufacturers...

high quality vertical suspended sump pump manufacturers 【high quality vertical suspended sump pump manufacturers】

Read MoreReduced inventory

high quality vertical suspended sump pump manufacturers...

high quality vertical suspended sump pump manufacturers 【high quality vertical suspended sump pump manufacturers】

Read MoreHow to choose a slurry pump?

high quality vertical suspended sump pump manufacturers...

high quality vertical suspended sump pump manufacturers 【high quality vertical suspended sump pump manufacturers】

Read MoreFine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

high quality vertical suspended sump pump manufacturers...

high quality vertical suspended sump pump manufacturers 【high quality vertical suspended sump pump manufacturers】

Read MoreDredge Pump

high quality vertical suspended sump pump manufacturers...

high quality vertical suspended sump pump manufacturers 【high quality vertical suspended sump pump manufacturers】

Read MoreAuxiliary equipment

high quality vertical suspended sump pump manufacturers...

high quality vertical suspended sump pump manufacturers 【high quality vertical suspended sump pump manufacturers】

Read MoreOn the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

high quality vertical suspended sump pump manufacturers...

high quality vertical suspended sump pump manufacturers 【high quality vertical suspended sump pump manufacturers】

Read MoreIf you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

high quality vertical suspended sump pump manufacturers...

high quality vertical suspended sump pump manufacturers 【high quality vertical suspended sump pump manufacturers】

Read More

Popular articles

- Depending on your own requirements, propeller seals, mechanical seals or packing seals can be used.

- Corrosiveness of the liquid or slurry mixture: More corrosive slurries will wear pump components faster and may dictate the choice of pump manufacturing materials.

- Discharge ports can be placed at 45 degree intervals and oriented in up to 8 different positions depending on your needs.

- 2. All have vertical pumps and horizontal pumps and can convey slurry.

- Dredge pumps are designed to transfer large quantities of fluids and solids.

- What is a dredging pump?

Latest articles

-

A >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

-

>Slurry pump impeller is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

-

Keep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

-

The Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

-

A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

-

We know that the right rubber and ceramic liners work very well. They also last longer and can withstand more demanding use. They can also be replaced, thereby extending the life of the pump while reducing operating costs. You can also customise your pump with a variety of ceramic parts, including bushings, pump housings, impellers, wet ends and even seals.

Links

- There are several ways to buy black insulation tape at an affordable price

In conclusion, choosing between silicone rubber tape and rubber repair tape depends on your repair needs and specific circumstances. TAPE, with its extensive experience and commitment to quality, is here to assist you in finding the right tape for the job, ensuring a successful and lasting repair.

Advantages of Polyethylene:

- One of the key advantages of butyl rubber roofing is its resistance to extreme weather conditions. It can withstand harsh temperatures, from scorching summer heat to freezing winter cold, without cracking or degrading. Its UV resistance prevents sun damage, while its ability to expand and contract with temperature changes ensures that it remains intact over time.

- Despite its robustness, fireproof adhesive tape is surprisingly lightweight and flexible, allowing it to conform to irregular surfaces without losing its effectiveness. Its non-toxic nature and eco-friendly composition further enhance its appeal.

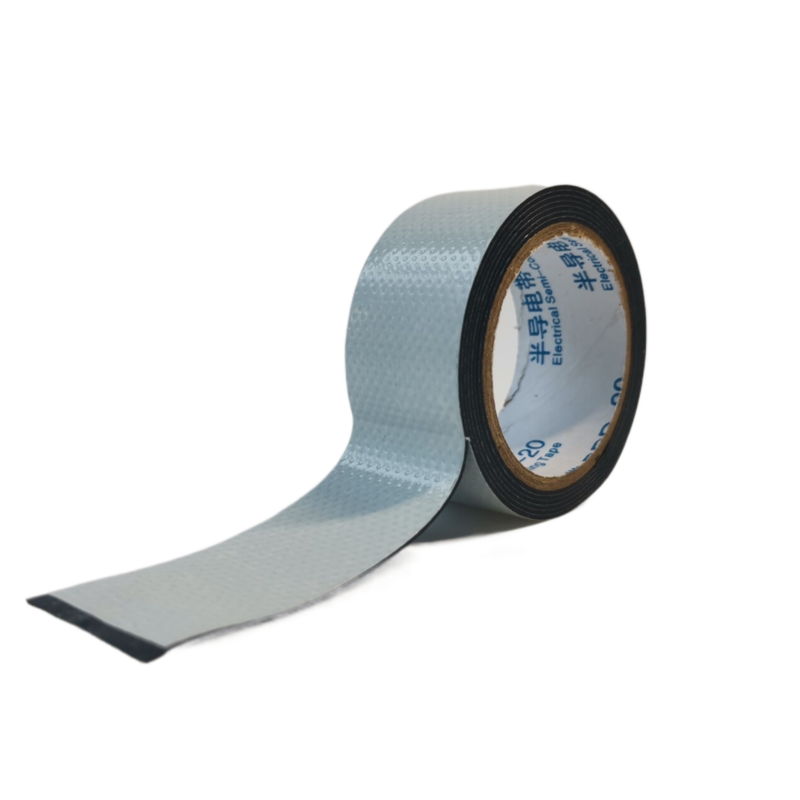

- Fabric electrical tape is a versatile and durable tool that is essential for anyone working with electrical wiring. Whether you are a professional electrician or a DIY enthusiast, fabric electrical tape can be an invaluable resource for protecting and insulating electrical connections.

Butyl Sealant tapeis crafted from butyl rubber, a man-made material that was first synthesized during the early 1900s in order to strengthen traditional rubber adhesives. This innovative product surpasses natural rubbers in its capacity to stay sticky at far colder temperatures - an impressive feature that sets it apart from other adhesive materials.

- One of the standout features of Flex Tape 4 is its ability to withstand extreme temperatures. Whether you are working in freezing cold conditions or scorching hot weather, Flex Tape 4 will maintain its adhesive strength. This makes it ideal for outdoor repairs and projects that require a strong, weather-resistant seal.

- The application of this tape requires a meticulous approach. Coaches and facility managers strategize the layout carefully, considering the flow of movement and the type of exercises performed. Precise measurements and straight lines are essential to avoid confusion and potential accidents during training sessions. The process of applying the tape is akin to an artist drawing on a canvas; each strip laid down is a stroke that contributes to the bigger picture of an efficient workout space.

- It's also important to apply the tape correctly. Start by cleaning the area around the wire or connection to remove any dirt or debris. Then, wrap the tape tightly around the wire, overlapping each layer slightly to create a secure seal. Be sure to cover all exposed areas completely, and avoid stretching the tape too much, as this can weaken its insulating properties.

- In the realm of electrical and electronic engineering, the use of cloth wiring harness tape has become increasingly prevalent. This versatile material offers a range of benefits that make it an ideal choice for a variety of applications.

2. Durability Made to withstand extreme temperatures and harsh environments, self-fusing rubber tape maintains its effectiveness and integrity over time. Its resistance to abrasion, UV radiation, and chemical exposure ensures longevity, even in challenging conditions.

- In the realm of household repairs and maintenance, few tools are as indispensable as rubber tape. This humble yet powerful material has become the go-to solution for fixing leaks and sealing pipes, making it an essential item in any toolbox. But what exactly makes rubber tape such an effective remedy for leaks? Let's delve into the world of this versatile tape and explore its benefits, applications, and limitations.

4. Wide Temperature Range

- High tension tape also plays a crucial role in sports and fitness. It is commonly used in physical therapy for injury prevention and rehabilitation, thanks to its ability to provide support without limiting mobility. In extreme sports, it is employed to secure gear or reinforce equipment.

- One of the primary applications of adhesive rubber seal strips is in the automotive industry. They are extensively used in car doors, trunks, and windows to prevent air and water leaks, reduce noise and vibration, and enhance overall vehicle comfort. Their ability to maintain their sealing properties under varying weather conditions makes them indispensable in automotive manufacturing.

Why is Butyl Sealant Tape Used?

- In addition to its practical applications, EPR self-amalgamating tape is also known for its durability. Once applied, the tape forms a strong and flexible bond that can withstand even the harshest conditions. This makes it a cost-effective solution for long-term repairs and maintenance projects.

- One of the most common uses for self-amalgamating silicone tape is for emergency repairs. Whether you have a leaky pipe, a damaged hose, or a broken electrical wire, this tape can provide a quick and easy fix. Simply stretch the tape around the damaged area, overlap the layers, and watch as it bonds together to create a watertight seal. This can help prevent further damage and buy you some time until a permanent repair can be made.

2. Ease of Application

Long lasting applications + great for quick fixes.

In addition to durability, it is important to consider the adhesive strength of the floor marking tape. Strong adhesive ensures that the tape stays in place and does not peel up or become a tripping hazard. Cheaper tapes may have weaker adhesive, which can lead to safety hazards and increased maintenance costs.

floor marking tape price

Its self-adhesive backing allows for quick and easy application, without the need for any additional adhesives or tools Its self-adhesive backing allows for quick and easy application, without the need for any additional adhesives or tools

Its self-adhesive backing allows for quick and easy application, without the need for any additional adhesives or tools Its self-adhesive backing allows for quick and easy application, without the need for any additional adhesives or tools flex tape gray. Simply clean the surface where you want to apply the tape, peel off the backing, and press it firmly into place. The tape will adhere securely to most surfaces, providing a strong and durable bond.

flex tape gray. Simply clean the surface where you want to apply the tape, peel off the backing, and press it firmly into place. The tape will adhere securely to most surfaces, providing a strong and durable bond.

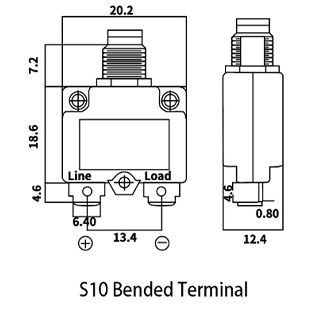

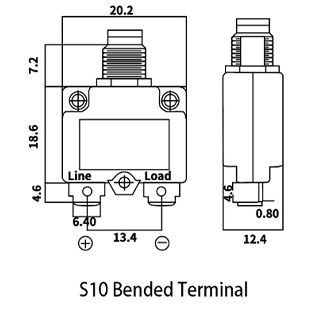

Choosing a Control Box

Marine:In the marine industry, butyl sealant tape is used to seal seams, joints, and gaps in boat and ship components, such as hulls, decks, and windows. The tape's water resistance and durability make it an excellent choice for maintaining the watertight integrity of marine vessels.

The pressure-sensitive adhesive ensures a secure bond, while still allowing for easy removal when necessary, without leaving residue behind The pressure-sensitive adhesive ensures a secure bond, while still allowing for easy removal when necessary, without leaving residue behind

The pressure-sensitive adhesive ensures a secure bond, while still allowing for easy removal when necessary, without leaving residue behind The pressure-sensitive adhesive ensures a secure bond, while still allowing for easy removal when necessary, without leaving residue behind pvc insulation tape black.

pvc insulation tape black.Many technicians opt for tape that can stretch without losing original form. This is helpful in wrapping wires because technicians must often stretch the tape around the cable, which needs to then return to its original form to provide a tight wrap. Lack of elongation can result in broken tape and uncovered cables.

What is Self-Fusing Rubber Tape?